- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 24-11-2022 Origin: Site

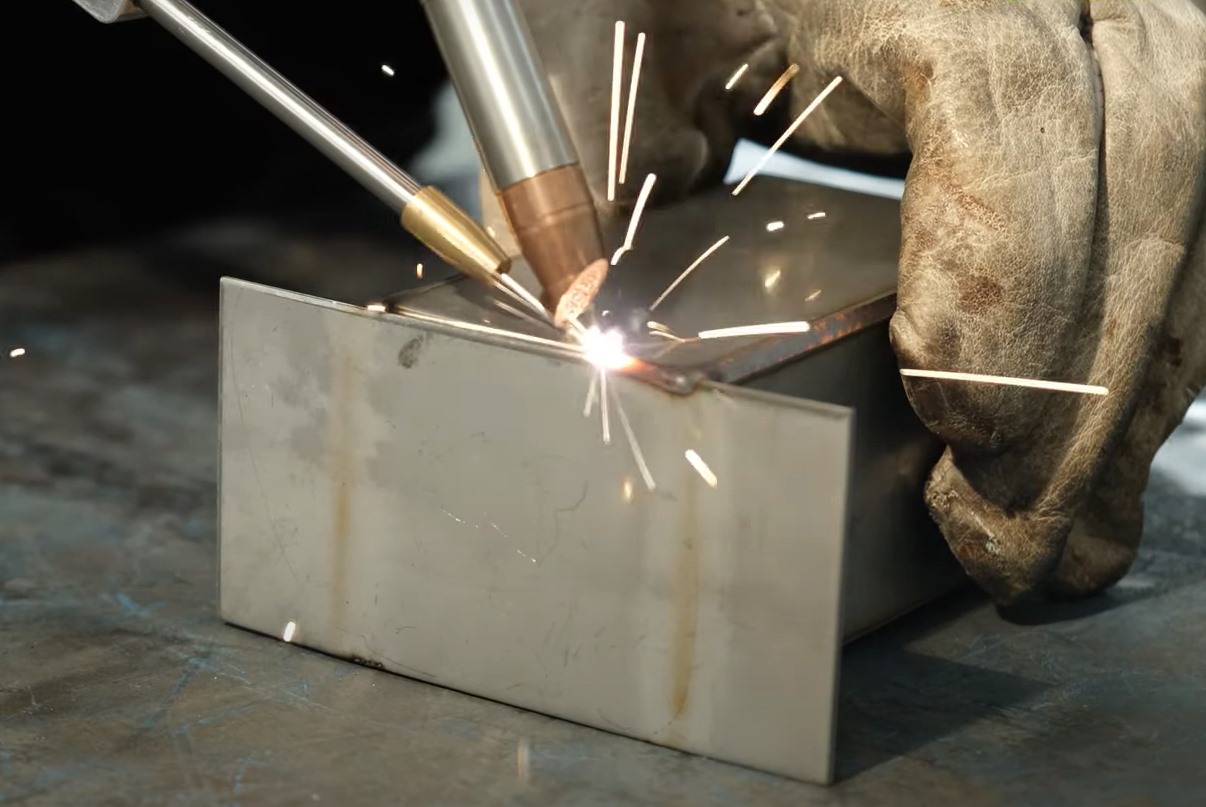

Handheld laser welding machines have gained prominence in various industries due to their precision and efficiency. These machines are essential tools for intricate welding tasks, offering the capability to fuse metals with accuracy and reliability.

The use of filler wires for laser welding, depending on the client's application, can generate the following benefits:

Improve the quality of the joints

In the case of welding stronger materials, the welded joints are much more resistant and qualitative.

Cracks will be avoided in the case of certain materials

In the case of laser welding with additional materials (wires) - the speed of the welding wires must be properly configured, depending on the thickness of the welded material and the speed at which the person wants to work. It will also depend on the type of welding you will be doing.

Handheld laser welding machines equipped with wire feed systems require the following consumables:

a. Welding Wire: Typically made of aluminum, welding wires come in various diameters such as 0.3mm and 0.6mm. A single large coil of welding wire can last for several months, making it a cost-effective consumable for extended use.

b. Copper Nozzles: Copper nozzles are positioned at the welding point and are integral to the welding process. Despite being consumed during the welding process, proper usage can extend the lifespan of a single copper nozzle to around 5-8 welding operations.

While not directly consumable, cooling water plays a vital role in extending the lifespan of the handheld laser welding machine. Using distilled or purified water with minimal impurities is recommended. This practice reduces the impact of impurities on the laser's longevity and overall performance.

The laser welding method is used in fields such as the automotive, aeronautical, medical, jewelry, etc. industries, and offers the deposition of a thin layer of addition without altering the properties of the base material. At the same time, it does not cause deformations of the base part, limiting the temperature induced in the material.

Low-alloy alloys for laser welding / (used especially in the aeronautical industry) in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

type 15CDV6

type 25CD4

Stainless alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

ER308L

ER312

ER316L

ER410

ER430

ER420

Nickel alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

ERNiCrMo-3

Aluminum alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

ER5356

ER4043

R-357.0

ER4047

Copper alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

CuAg1

Titanium alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

ERTI-2 / 4951 (grade 2/laser welding)

Cobalt alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of rods or small rolls D100:

5796 (cobalt alloy for laser welding)

Hardening & repair alloys for laser welding / in diameters from 0.2mm to 0.6mm in the form of sticks or small rolls D100:

HRC 48 / 819BS

HRC 36 / BMS

HRC 60 / MV5S

HRC 35/50 / MARVAL 18S

HRC 58 / SMV3S

HRC 53 / HBF17

For any price for whole laser solution, do not hesitate to contact us.

For laser welding products catalog,Click Here