- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

MH-LM900UV

Abedar Laser

| Availability: | |

|---|---|

Product Description

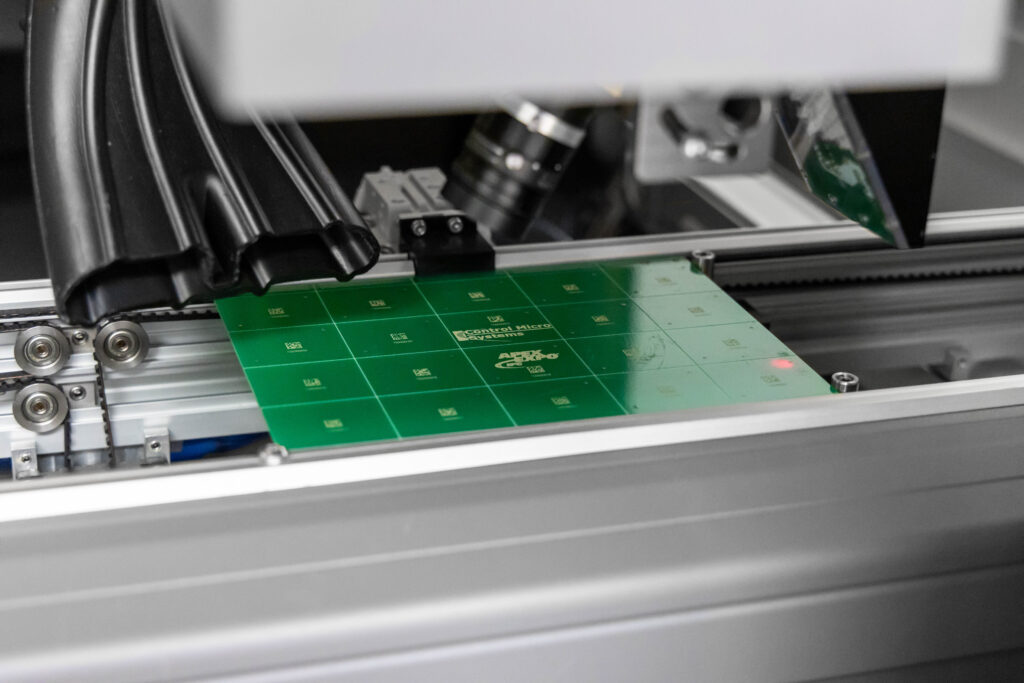

UV laser cutting depaneling machine of PCB boards is a method for cutting smaller circuits out of an entire circuit board array. Replace traditional mechanical routing techniques with a non-contact, high-precision laser depaneling system. Abedar Laser develops laser marking and cutting solutions for PCB manufacturers around the world.

PCB UV laser Systems are instrumented with machine vision software for marking or cutting areas on circuit boards with ease. These systems can be installed inline or with no patient involvement and can be customized upon request.

Advantages

1) UV Laser cutting source with machine vision for detecting board fiducial markings

2) CO2 or UV laser sources available based on applications lab testing results

3) PCB conveyor capable of carrying boards up with different production size

4) Automatic board entry/exit slots with safety interlocks

5) PCB UV laser systems configured for standalone operation.

6) Welded steel framework attached to aluminum for long-lasting use in industrial-grade

7) Class 1 laser workstations with emergency stop push button.

8) The operation of software with 19” monitors, keyboards, or touchscreen displays is the norm.

Parameters

Product Name | PCBs UV Laser Depaneling Machine |

Model | MH-LM900UV |

Laser Type | UV |

Wavelength | 355nm |

Max Power | 20W |

Pulse Repetition Rate Range | 40-300kHz |

Output Spot Size | 6mm(10X) |

Effective Platform Travel | 500mm*500mm |

Table Positioning Accuracy | ±0.003mm |

Table Repeatability | ±0.002mm |

Visual Positioning Accuracy | ±0.003mm |

Single Processing Format | 70X70mm |

Maximum processing width | 400mm*400mm (Customzied) |

Cut spot size | 0.03mm ± 0.003mm |

Dimensions | 1520mmX1370mmX1907mm |

GW | 1600KG |

Power Supply | 380V/3P Or 220V 50Hz |

Water Chiller | Pure Water 25L |