- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 23-10-2023 Origin: Site

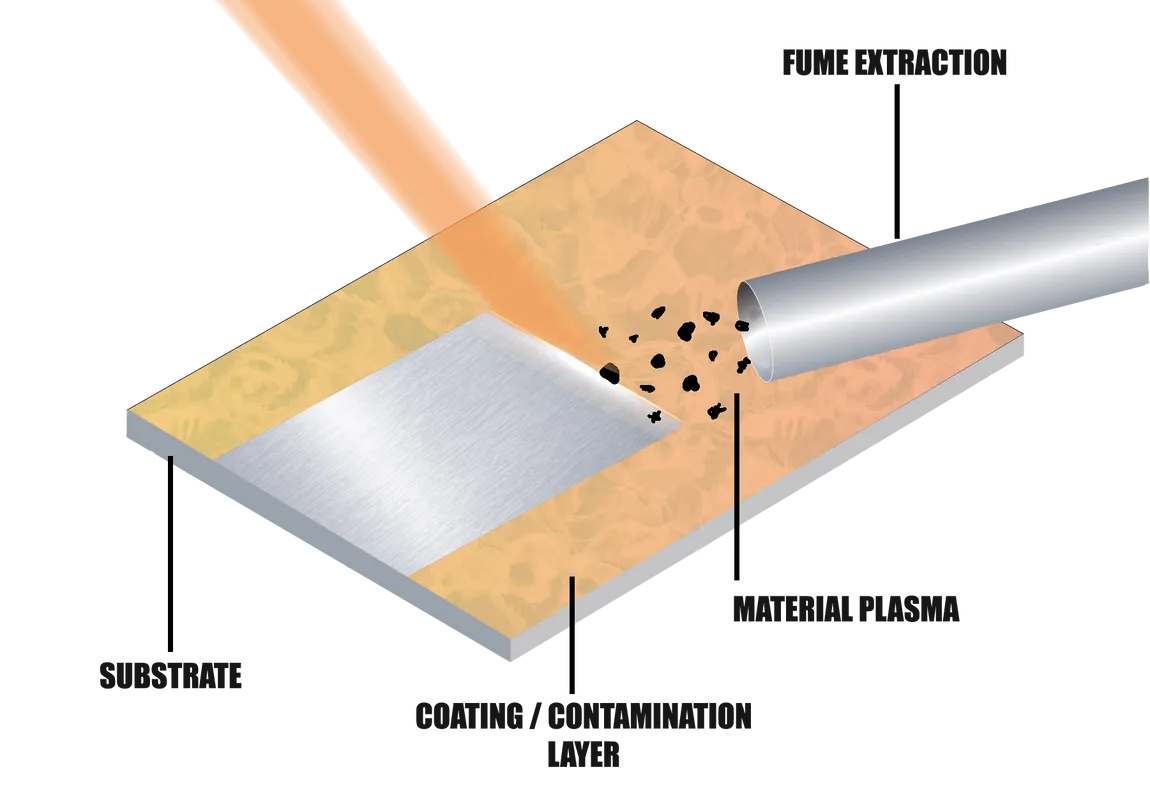

Pulse laser cleaning machine, which utilizes the principle of stimulated emission, is a device that amplifies or oscillates light in certain excited materials. Laser systems can be categorized into single-mode and multi-mode types.

Difference between Single-Mode and Multi-Mode:

Single-mode lasers emit a typical Gaussian beam with highly concentrated energy, resembling a steep mountain peak, and exhibit superior beam quality compared to multi-mode lasers.

Multi-mode lasers, on the other hand, combine multiple Gaussian beams, resulting in an energy distribution resembling an inverted cup, which is relatively more uniform. However, multi-mode lasers generally have lower beam quality compared to single-mode lasers.

Elliptical-shaped semiconductor lasers belong to the single transverse mode category, while multi-transverse mode lasers are typically rectangular in shape, with variations in the brightness and darkness of the beam profile.

Multi-mode lasers simultaneously generate two or more modes of emission. The design of multi-mode lasers differs from that of single-mode lasers, often featuring larger discharge tube diameters to reduce diffraction losses in higher-order modes and achieve high power output.

Single-mode lasers are mostly used for low to medium power applications, while high-power products are often based on multi-mode lasers.

Applications vary for single-mode and multi-mode lasers based on their distinct characteristics.

For instance, in the field of cutting, single-mode lasers offer significantly better processing efficiency compared to multi-mode lasers (typically 15% to 20% faster),High-power multi-mode lasers perform better in terms of both quality and efficiency.

In the context of pulse lasers, multi-mode lasers offer a more uniform energy distribution in the beam profile, approximating a flat-top beam pattern.

This characteristic makes multi-mode lasers less likely to cause damage to the substrate during the cleaning process.

Tire mold cleaning processes require strict adherence to quality standards because clean molds are essential for producing high-quality products. Mold cleanliness directly impacts the quality level of the tires produced. When using laser cleaning, it is essential to ensure that the process does not damage the mold's surface, alter its roughness, and maintains a uniform metallic appearance post-cleaning.

If laser selection and cleaning parameters are not appropriately chosen, there is a risk of damaging the mold after cleaning.

If you are unsure about selecting the right laser power and whether to use a single-mode or multi-mode laser, please provide details about your specific application. Our technical team will offer the most suitable solution. Contact Us Today!