- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 03-01-2024 Origin: Site

Laser cleaning, as an eco-friendly and efficient cleaning method, is gaining widespread acceptance across various industries, gradually replacing traditional methods such as sandblasting and chemical cleaning. Abedar Laser, a high-tech enterprise specializing in research, development, production, and sales, has introduced innovative laser cleaning products with applications in industries ranging from mining and shipbuilding to aerospace and mechanical manufacturing.

Environmental Impact:

Traditional methods like sandblasting generate significant dust and environmental pollution during the cleaning process, adversely affecting both the surroundings and human health. In contrast, laser cleaning not only eliminates these environmental concerns but is also user-friendly and easy to learn.

Technological Innovations:

Abedar Laser has secured numerous domestic and international patents for its laser cleaning technology, breaking new ground in the field. The handheld laser cleaning devices, characterized by their compact size, ease of operation, and reasonable prices, have garnered popularity among various enterprises.

Efficiency and Precision:

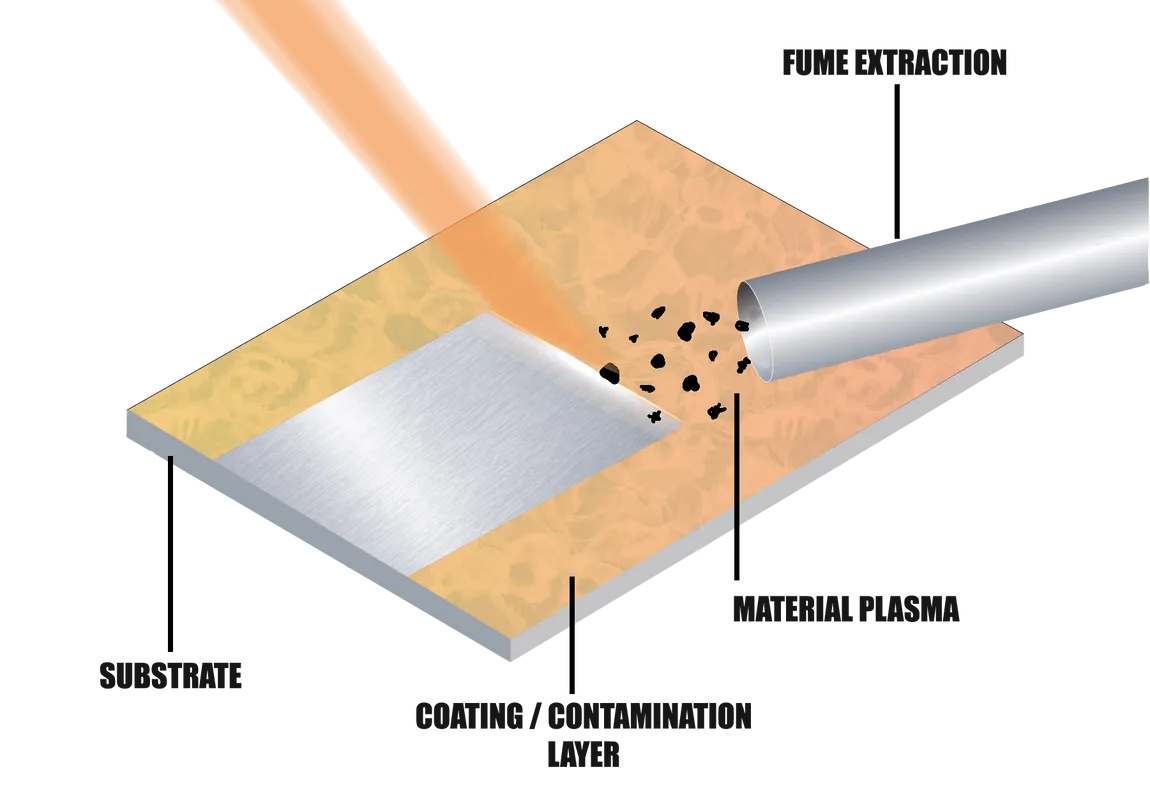

The principle behind laser cleaning involves directing high-frequency, high-energy laser pulses onto the surface of the workpiece. This process efficiently removes contaminants such as oil, rust, or coatings by causing them to evaporate or peel off without harming the metal substrate. Unlike sandblasting, laser cleaning achieves this without causing any damage to the base material.

Operational Advantages:

While laser rust removal machines may initially have a higher cost, they offer long-term stability, low operational costs, rapid cleaning speeds, and high efficiency. Laser cleaning requires only one operator, ensuring a safe and pollution-free working environment. In comparison, sandblasting operations are often accompanied by dust-related hazards and environmental pollution.

Surface Treatment Considerations:

In metal surface treatment, traditional methods like sandblasting and chemical cleaning involve consumable replacements, potential damage to workpiece surfaces, and challenges in ensuring thorough cleaning. Laser cleaning, however, requires no mechanical contact with the workpiece, preventing any damage. It is versatile enough to cater to the cleaning needs of flat or intricately curved surfaces, effectively preventing secondary oxidation and enhancing surface mechanical properties.

Cost-effectiveness:

Despite the initial higher investment in laser cleaning systems, their long-term stability, low running costs, fast operation, and high efficiency lead to a quicker return on investment compared to sandblasting methods. Over the long term, laser cleaning proves to be a more cost-effective solution.

The technological advancements and environmental benefits offered by handheld laser cleaning machines make them a superior choice over traditional sand blast machines for surface treatment applications. As industries continue to prioritize efficiency, cost-effectiveness, and environmental sustainability, the adoption of laser cleaning technology is expected to grow exponentially.

If you need to select the right solution, Contact Us Today!