- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

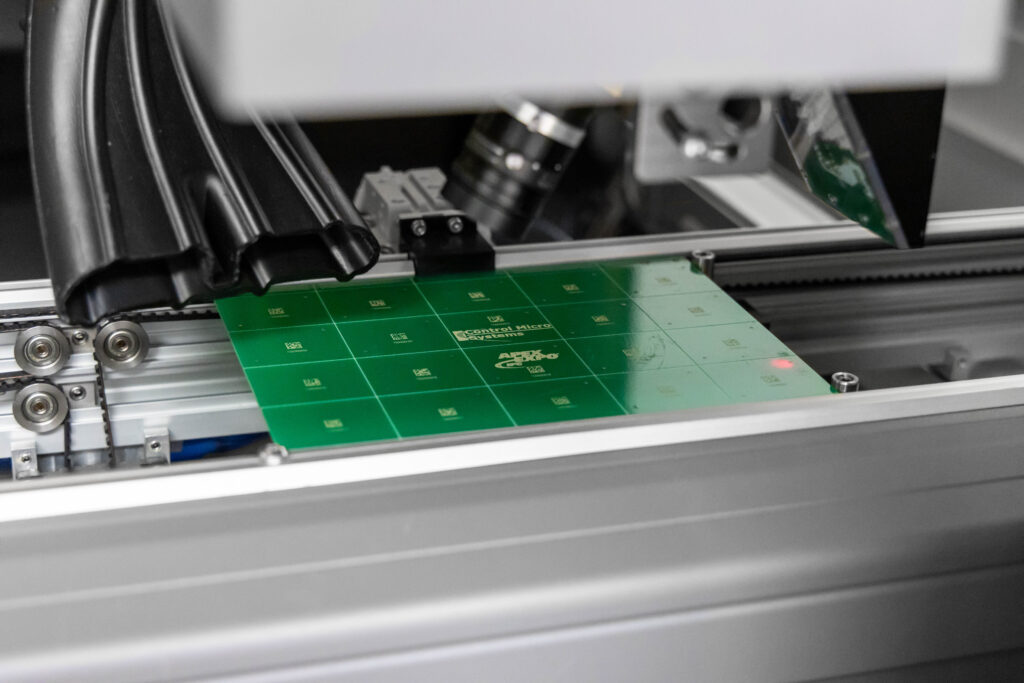

MH-LM900UV

Abedar Laser

| Availability: | |

|---|---|

Product Description

Advantages

Use a high-quality laser pcb depaneling machine: The laser is the heart of the depaneling machine, and using a high-quality UV laser will ensure that the cutting process is precise and accurate.

Optimize laser parameters: The laser pcb depaneling machine, such as power, frequency, and pulse duration, can be adjusted to optimize the cutting effect for the specific PCB being processed.

Ensure proper alignment: Accurate alignment of the laser pcb depaneling machine is crucial to ensure that the laser cuts along the correct path. Some machines come with automatic alignment features, but manual adjustments may be necessary for some PCBs.

Use the correct cutting method: There are several laser pcb depaneling machine available, including full cut, partial cut, and trench cut. Choosing the correct cutting method for the specific PCB being processed can improve the cutting effect.

Maintain the machine: Regular maintenance of the depaneling machine is important to ensure that it is operating at peak performance. This includes cleaning the optics, replacing worn parts, and checking for proper alignment.

Parameters

PCBs UV Laser Engraving Machine | |

Model | MH-LM900UV |

Laser Type | UV |

Wavelength | 355nm |

Max Power | 20W |

Pulse Repetition Rate Range | 40-300kHz |

Output Spot Size | 6mm(10X) |

Effective Platform Travel | 500mm*500mm |

Table Positioning Accuracy | ±0.003mm |

Table Repeatability | ±0.002mm |

Visual Positioning Accuracy | ±0.003mm |

Single Processing Format | 70X70mm |

Maximum processing width | 400mm*400mm (Customzied) |

Cut spot size | 0.03mm ± 0.003mm |

Dimensions | 1520mmX1370mmX1907mm |

GW | 800KG |

Power Supply | 380V/3P Or 220V 50Hz |

Water Chiller | Pure Water 25L |