- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 17-01-2024 Origin: Site

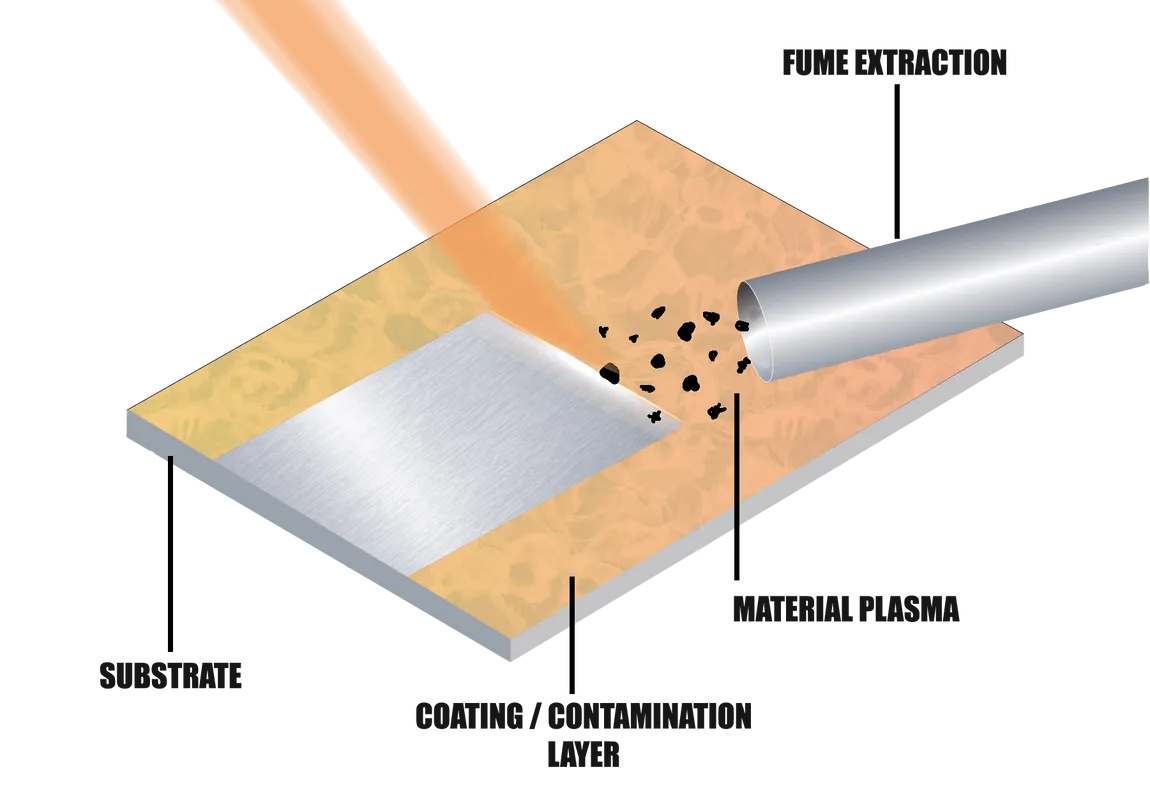

The laser rust removal process is actually a process of interaction between laser and material. According to the optical properties of the contaminants and the base material, determine the appropriate laser wavelength and appropriate laser energy density to achieve the purpose of removing contaminants without damaging the base material. For lasers of specific wavelengths, the absorption rates for different substances are different. Only by selecting the laser wavelength with the strongest absorption ability of pollutants can the purpose of decontamination be achieved.

At the same time, the laser energy density must be between the cleaning threshold and the damage threshold to achieve the purpose of cleaning. If the laser energy is lower than the cleaning threshold, no matter how long the laser is irradiated or how many times it is scanned, it will not be able to remove rust or dirt. If it is higher than the damage threshold, it will exceed the melting point of the substrate and damage the substrate. The selection of laser rust remover is based on the contaminants and substrate. The wavelength, repetition frequency, pulse width, and peak power of the laser will all affect the rust removal effect. What impact do each parameter have on rust removal operations?

The absorbance of the material is closely related to the wavelength of the laser. The shorter the wavelength, the greater the energy of the photon, and the chemical effect is enhanced, which can easily break the molecular bond. On the contrary, the longer the wavelength, the energy of the photon gradually decreases, and the thermal effect increases. The thermal effect of the laser increases. The penetrating ability is also enhanced.

Lasers with different wavelengths have different absorption peaks for conductors, semiconductors, and insulators. The wavelength selection is based on the characteristics of the pollutants that need to be removed.

In laser cleaning, laser average power and peak power are very important parameters. The greater the power, the higher the rust removal efficiency. For example, the rust removal efficiency of a 2000-watt machine is close to twice that of a 1000-watt machine. Compared with power, laser energy density is a more important value. Laser energy density must be between the cleaning threshold and the damage threshold. Laser rust removal machines have two types of lasers, one is a continuous laser and the other is a pulse laser. At the same power, pulse lasers can radiate higher energy laser beams. However, pulse lasers are much more expensive than continuous lasers, and the price-performance ratio is almost the same.

repetition frequency and mode. These parameters vary depending on the substrate material and contaminants. If the repetition rate is too low, the operating efficiency will be lower, and if the pulses are narrow, the peak power will increase accordingly. The laser mode has a large divergence angle and is not easy to focus. The divergence angle is small and the spot intensity is high. It is easy to cause damage to the base at the center point without cleaning the surrounding areas. Among them, the pulse width has a greater influence. For example, when the other parameters are the same, the pulse width is 100ns, the rust temperature rises to 2000 degrees, and the pulse width is 10ns, the temperature rise reaches 7000 degrees.

Laser rust removal is a process that combines theory with practice. It requires continuous testing during actual operations to determine the optimal parameter configuration to achieve the purpose of removing contaminants without damaging the base material. As a professional complete solution provider of laser equipment, Abedar Laser can provide perfect solutions according to the actual needs of customers.

As environmental protection policies become more and more stringent, traditional rust removal processes are facing elimination. Laser rust removal is an environmentally friendly green process that meets the requirements of sustainable development. It has occurred rapidly in recent years and has been included in the 2025 China Manufacturing Industry Catalog and is regarded as a key development area. industry. Not only is it environmentally friendly, it is also cost-effective. Laser rust removal is expected to become the lowest-cost rust removal method.

Laser rust removal consumables are low, and the main cost comes from the purchase cost of the laser rust removal machine. With the localization of the laser, the core component of the laser rust removal machine, the price of the laser rust removal machine has dropped significantly, falling by more than 60% in the past three years. For example, Abedar Laser laser removal machine There were 120,000 rust removal machines three years ago, and now there are more than 40,000 rust removal machines. According to this trend, laser rust removal will soon become the mainstream process of rust removal, and laser rust removal machines will soon be more popularly used.

If you need to select the right solution, Contact Us Today!