- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

YEARS EXPERIENCE

PATENTS

COUNTRY

Applications request is the most important information for CNC laser machines,with professional laser machine sales team,we will guide client how to choose perfect solution for different CNC Laser equipments.

CNC Laser Machines Orders could be produced according clients' requests strictly.48 Hours running test & 72 Hours Aging test before Laser machines shipment out.

Flash Disk & User Manual will be sent to clients to help them better use the CNC Laser Machines;

Lifetime software free upgrades.

We would like to take this opportunity to be advised that our company will be closed from 1st,May to 5th, May, in observance of the International Labour Day.

We would like to express our heartiest thanks for your great support and hope you guys have great holiday with your family!

Abedar Laser's handheld pulse laser metal cleaner utilizes high-energy laser beams to target surface contaminants on metal materials. By concentrating laser energy in both time and space, it rapidly vaporizes, decomposes, or dislodges surface impurities. This technology finds extensive applications in sectors like aviation, shipbuilding, automotive, and tire manufacturing, particularly for large objects. Whether addressing superficial rust or deep-seated corrosion, the Abedar Laser Pulse Laser series offers various laser power levels, enabling users to tailor the cleaning process to their specific needs.

Single-mode and multi-mode, in the context of lasers, refer to the types of modes the laser operates in. Within a laser device, the propagation of the laser beam can either adhere to a single mode or be a mixture of multiple modes. A laser with a single propagation mode is aptly termed a single-mode laser, whereas a laser supporting multiple propagation modes is dubbed a multi-mode laser.

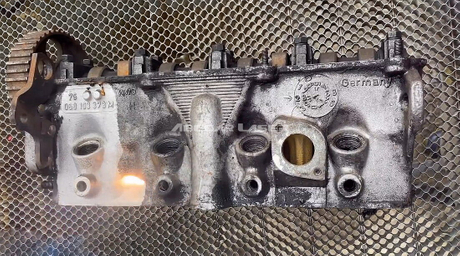

Laser cleaning emerges as a pivotal method, utilizing high-energy laser beams to swiftly evaporate and remove stains, rust, residues, and other contaminants from mold surfaces without affecting their precision or quality.Traditional methods like mechanical polishing and chemical cleaning often suffer from low efficiency and the risk of damaging molds. In contrast, laser cleaning, characterized by its non-contact, non-abrasive, and heat-free nature, offers significant advantages in mold cleaning.

Laser printing machine for plastic involves using a chemical solution or abrasive material to remove layers of the ABS plastic surface, leaving behind a permanent engraved mark. It's a relatively simple and cost-effective method but may not produce as precise results as laser engraving.

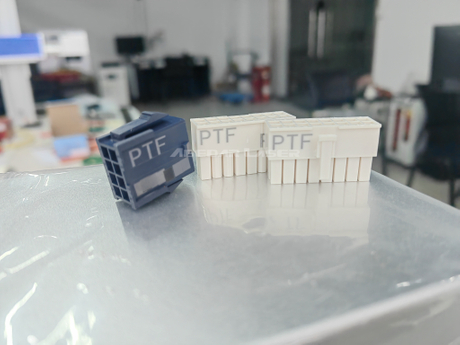

FPC is an important interconnection circuit in the field of electronics, essential for electronic circuits. CVL cover film is a partner of FPC, attaching it to FPC products can prevent oxidation and solder resist. 5W UV laser marking machine equipment can easily solve this problem, meeting the requirements of product quality traceability and after-sales service coding marking.